Point-by-point wire arc additively manufactured (WAAM) steel connections

Contact person

Project description

The fast-developing field of digital design and robotic fabrication opens novel manufacturing possibilities for the building sector that are worth exploring. At ETH Zurich, the Gramazio Kohler Research Group has investigated adaptive detailing for robotic assembly of spatial metal structures. They have focused on point-by-point wire arc additively manufactured (WAAM) connections between custom-oriented hollow-section steel profiles. More details on this research project can be found here. Such connections could allow novel force-flow optimized joints in future lightweight free-form building envelopes.

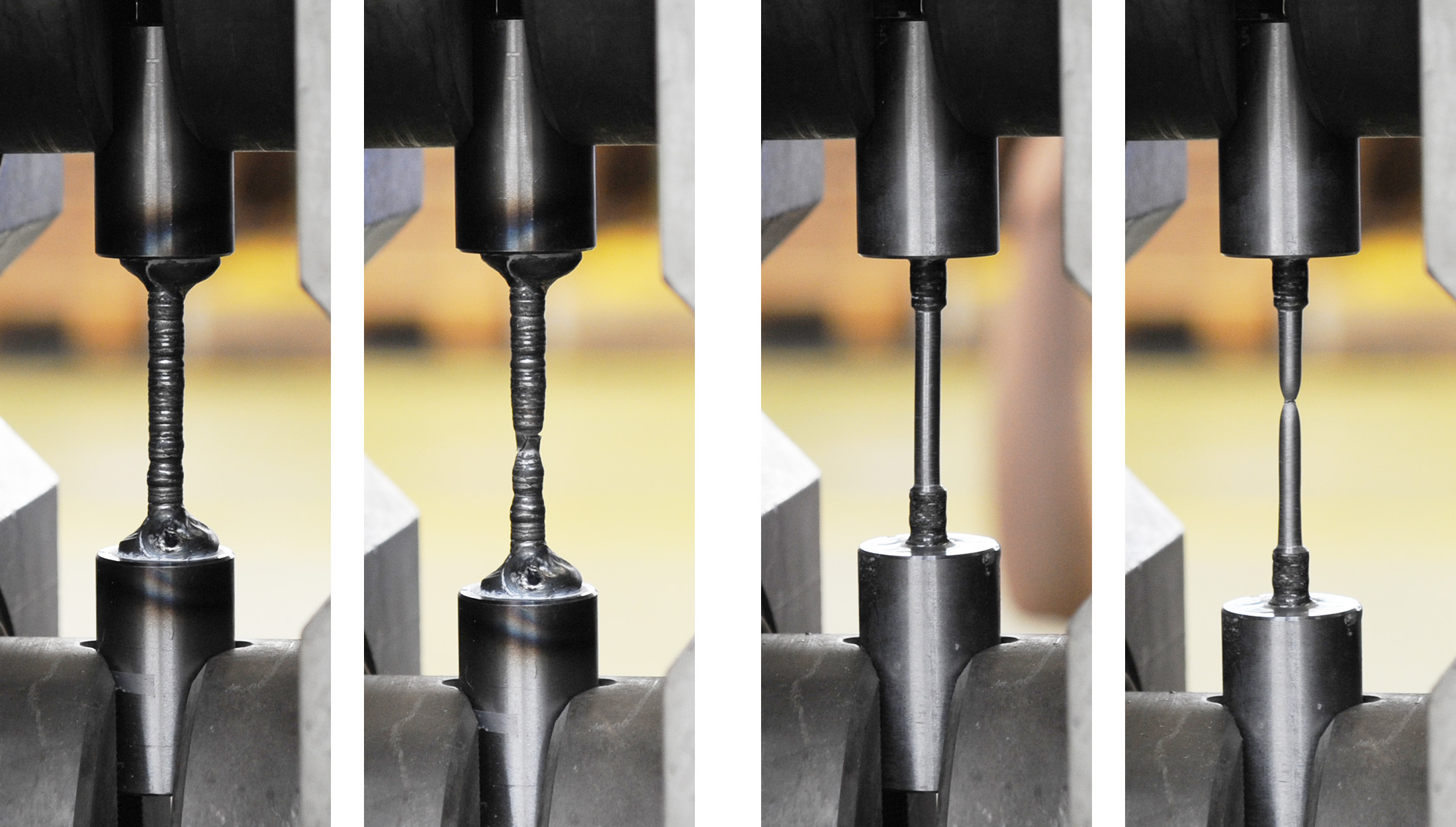

In a collaboration with the Gramazio Kohler Research Group (Institute of Technology in Architecture) and the Durability of Engineering Materials Group (Institute for Building Materials), we have performed uniaxial tensile and compressive tests on point-by-point wire arc additively manufactured (WAAM) bars, as parts of the above mentioned novel connections, to determine their mechanical properties. Furthermore, we focused on assessing the geometrical quality of such WAAM bars by 3D-scanning and on developing a suitable workflow for investigating the columns in finite element simulations.